Command

The direct connection to the "U" axis of the numerical control of the machine tool allows to perform any type of turning operation, boring, internal and external facing, threading, radius and spherical operations.

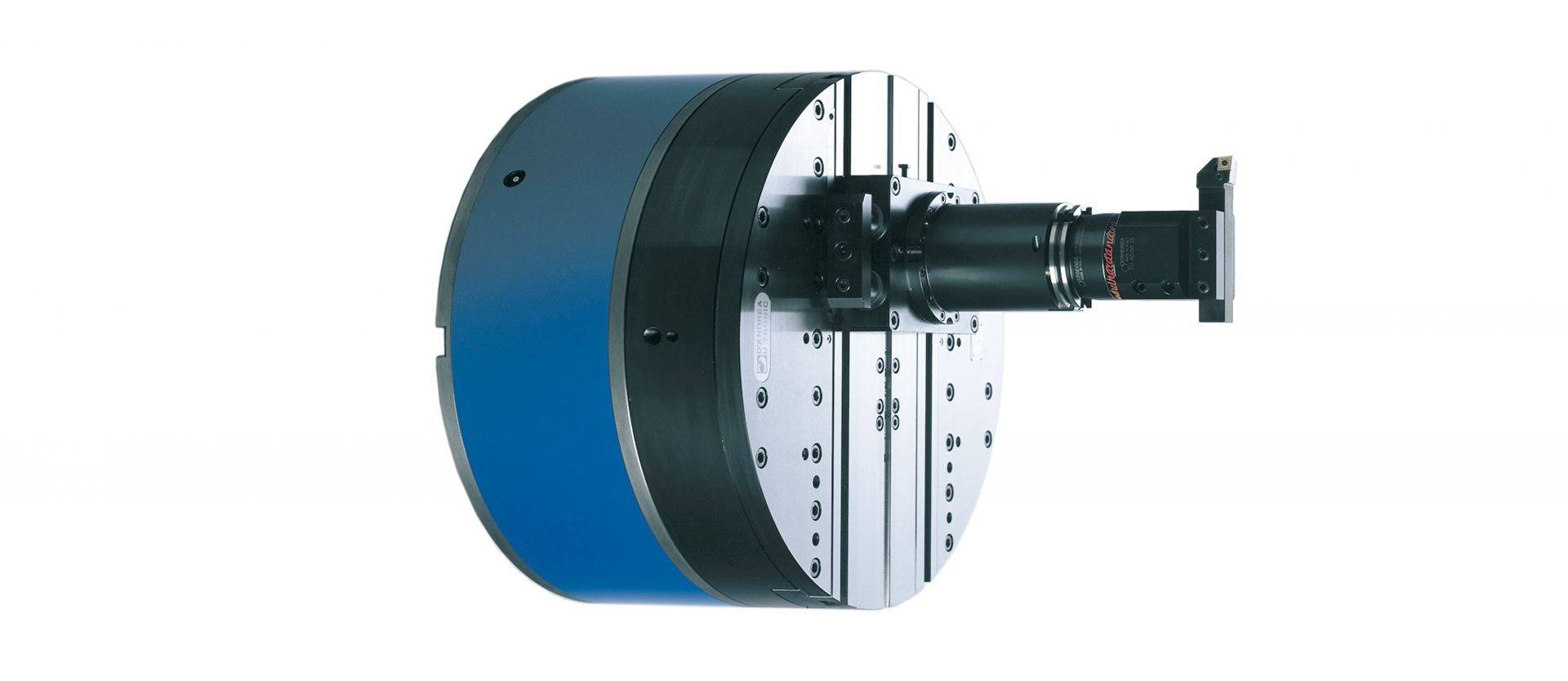

Medium and large Numerical Control heads for boring and facing, applicable on boring machines, machining centers and special machines.

General features

U-TRONIC are medium and large sized CN heads that are connected to the U axis of the CNC in the tooling machine for outer facing, inner facing, back-facing, cylindrical and conical boring and threading, concave and convex radius machining through the interpolation with the other axes of the machine tool.

They can be applied manually or automatically and with pallet systems on boring machines, machining centers and special machines. They are produced in 6 standard models from ø360 to ø1000 mm, all with internal coolant way.

In addition to the standard range, special version can be provided: big-sized up to 1.600mm diameter, with integrated reduction gear and, upon request, with hole, double slide and with counterweights for self-balancing. Toolholders may be applied on the slide, with either manual or automatic tool change.

Internal pressurization

To prevent liquid and dust from getting into the servomotor, transducer and limit switch areas, an Ø 8,5 hole is provided for internal pressurization of the fixed body with an air inlet at 0.5-1 BAR.

Automatic greaser

A Ø 8,5 hole is provided on the head so that grease can be automatically put into the U-TRONIC.

Coolant supply

Internal coolant channels are provided inside the U-TRONIC head that allow coolants to pass through from the machine spindle up to the two threaded holes located next to the slide. Tubes can be screwed on these holes to bring coolant directly to the tool. Max pressure BAR 40.

The application requires an interface flange that can be provided in manual, automatic, extended and angular versions.

The U-TRONIC can also be equipped with an automatic tool change mounted on the slide to obtain a complete automation.